Throughout the intensive environment of assembly, operation and delivery are crucial. To address these necessities, contemporary building equipment has advanced to provide unsurpassed efficiency and dependability. State-of-the-art first-rate building device offerings are equipped with sophisticated tools elevating operation and diminishing ecological disruption. Ranging from robust diggers and haulers to nimble lifts and small-scale machinery, these contraptions are structured to address the most involved fabrication projects easily.

- Advanced hydraulics allow for smooth and precise operation, resulting in increased accuracy and reduced downtime.

- Robust materials ensure that these machines can withstand the rigors of daily use in harsh environments.

- Green innovations minimize the environmental footprint of construction activities.

Concrete Batch Operations: Constructed for Reliability

Concrete mixing facilities function as the fundamental backbone of infrastructure ventures, guaranteeing concrete is synthesized accurately and uniformly. These intricate designs apply numerous contemporary elements to elevate output within the concrete construction process. From the precise measurement of ingredients to the efficient mixing and discharge processes, concrete batching plants are engineered to deliver high-quality concrete that meets the demanding requirements of modern construction. By automating necessary steps and decreasing human engagement, these apparatuses confirm stable output while promoting full-scale efficiency.Stabilized Soil Plant Mixers Delivering Durable Foundations

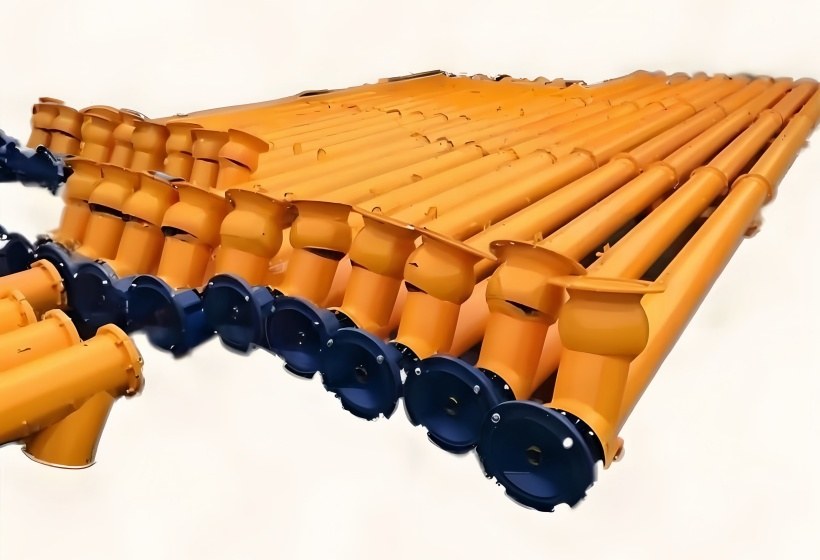

In the realm of construction, stability is paramount. When it comes to building durable foundations, stabilized soil mixing plants emerge as a prime choice. These versatile machines capably fuse solidifying additives with local ground, forming a durable structure designed to survive harsh elements and time.

Offering unparalleled strength and longevity, stabilized soil mixing plants contribute in a wide range of projects, including roads, bridges, pavements, and residential/commercial structures. By capitalizing on the organic power of dirt, these apparatuses furnish an eco-conscious solution for footing development.

Concrete Manufacturing Options for Different Endeavors

We grasp each fabrication assignment is exclusive and demands adapted cement formulas. Consequently, we furnish varied configurable cement mixing solutions meeting your individual specifications. Whether you're working on a large-scale infrastructure project or a smaller, localized endeavor, we have the expertise and equipment to deliver high-quality concrete consistently. Our ensemble of consultants teams with customers to formulate building material facilities maximizing operation, limiting waste, and accomplishing exceptional outputs. We offer a variety of components, including batching systems, mixing units, aggregate handling equipment, concrete pumps, control and monitoring systems. Our enthusiasm for customer pleasure is consistent. We commit to delivering comprehensive assistance from first engagement to setup and continuous servicing. Enable us to aid your advancement, piece by piece.Mobile Batching Plants: Dynamic and Versatile

Inside the fabrication environment, performance and resilience are significant. Transportable concrete batching plants provide an incomparable approach to these demands, allowing contractors exceptional versatility and mobility at sites. Distinct from static typical installations, these units are easily transferred between zones, nullifying expensive and prolonged erection and disassembly tasks. This allows for streamlined operations, reduced project durations, and significant cost savings.

The transportability of movable concrete production systems unlocks various avenues for constructors. They allow competent servicing of ventures in remote places, narrow city settings, or wherever permanent facilities are unworkable. Furthermore, the option to rapidly move systems between projects enables constructors to enhance resources and lower inactivity.

- Elevated Efficiency: Minimize travel time and get projects moving faster with on-site mixing.

- Lower Expenses: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Greater Adaptability: Tackle a wider range of projects in diverse locations.

Possessing their miniature size and tough efficiency, portable concrete batching facilities disrupt the fabrication environment. They supply constructors with implements needed to realize assignments skillfully, affordably, and with continual accuracy.

Exact Concrete Fabrication Using Modern Innovations

Present-day concrete processing sees a profound change owing to incorporation of sophisticated equipment. Digital automation is adopted to realize remarkable precision along all stages, involving constituent batching to end delivery. Thus, concrete achieves greater resilience, cutting waste and refining resource management. Data analytics serve vital purposes in acquiring live feedback on diverse factors throughout fabrication. The feedback is evaluated to detect possibilities for fine-tuning, facilitating fabricators to continuously upgrade procedures and supply uniformly excellent concrete. The benefits of precision concrete production extend beyond the manufacturing process itself. Enhanced factors of innovative concrete bring about strong architectures, minimizing upkeep outgoings and lengthening construction durability.Fostering an Environmentally Responsible Future via Modern Construction Devices

The building sector experiences a significant evolution, fueled by the pressing demand to reduce its ecological footprint. State-of-the-art assembly instruments influence significantly this transformation towards environmental care. Electric-powered machines are becoming increasingly commonplace, reducing emissions and noise pollution. Besides, enhancements in construction yield superior apparatuses that manage resources sensibly. This evolution fosters ecological balance and raises productivity for erection companies.

The adoption of sustainable practices in the construction sector is essential for creating a livable future. With the adoption of state-of-the-art devices and approaches, the industry assists in safeguarding nature for posterity.

The Key Associate in Building Ventures: Resilient Equipment, Knowledgeable Aid

For erecting next-generation infrastructure, steadfast associates are important. Our team offers that help. Our inventory features tough resilient apparatuses developed to manage complicated undertakings. Our tools feature cutting-edge innovation guaranteeing peak productivity and function.

But we're more than just equipment suppliers. Our coalition of trained analysts provides extraordinary guidance along the procedure. From evaluation to upkeep, we guide you in refining your erection schemes.

- We provide thorough coaching workshops to enable your workforce for safe and optimal apparatus operation

- We also offer remote expert assistance to resolve your inquiries and issues promptly

- Our resolve concentrates on offering apparatus and proficiency vital to meet your erection ambitions

High-Capacity Cement Batching

Vast fabrication undertakings necessitate cement strategies designed to tolerate heavy stress and pressure. Robust cement mixing systems meet this demand by providing durable blends customized for overpasses, tall buildings, and passageways. Such particular systems use tough devices equipped to deal with extensive supplies of elements, binders, and modifiers. Meticulous assessments copyright consistent standards and compliance with rigorous erection laws

- Innovative control devices elevate mixing accuracy and effectiveness

- Utilizing premium mortars increases the strength of the composite

- Solid concrete production units assist fundamentally in development enhancement influencing regular living

Perfecting Building Procedures: Advanced Concrete Preparation and Delivery

Amid the quick sphere of creation, capacity is crucial. A key aspect of achieving this lies in optimizing your mixing and delivery processes. By utilizing effective strategies, you will noticeably minimize leftovers, reduce outlays, and boost comprehensive performance. A key point is selecting appropriate batching machinery for your particular requirements. Be it a compact blender for small projects or a powerful unit for wide operations, confirm it accommodates the volume of materials demanded. Also, perfect your transport routes to decrease transit times and energy expenses.

- Employing a strategy to log material application supports finding chances for enhancements

- Scheduled upkeep of your blending and distribution tools is vital to preserve best functionality and lifespan

Complete Concrete Construction Process

Inside the domain of infrastructure, concrete acts as a foundation of solidity and endurance. Furnishing full-range solutions across your concrete project is our enthusiasm. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,

Throughout the strenuous field of development, capacity and accomplishment are key. To comply with these expectations, present-day fabrication machinery has innovated to provide unequaled operation and consistency. Present advanced fabrication tools selections are equipped with modern solutions advancing capacity and decreasing natural impact. Encompassing durable scoopers and lifters to agile winches and compact contraptions, these implements are developed to execute the most demanding construction activities with simplicity.

- Enhanced mechanical drives allow for smooth and precise functionality, resulting in increased accuracy and reduced downtime.

- Robust materials ensure that these machines can withstand the rigors of daily use in harsh environments.

- Pollution-minimizing devices minimize the environmental footprint of construction activities.

Batch Plants for Concrete: Tailored for Effectiveness

Concrete mixing installations represent the fundamental base of construction tasks, ensuring concrete is manufactured with exactness and regularity. These advanced platforms incorporate various innovative devices to amplify capacity throughout the concrete formulation steps. From the precise assessment of constituents to optimized fusion and emission activities, concrete manufacturing units are constructed to offer excellent concrete complying with exacting standards in present-day erection. By streamlining essential operations and reducing human involvement, these systems guarantee uniform yield while boosting total efficiency.Stabilized Soil Mixing Plants Delivering Durable Foundations

Across the area of assembly, strength is fundamental. When it comes to building durable foundations, stabilized soil mixing plants emerge as a leading solution. These versatile machines skillfully amalgamate soil enhancers with native dirt, creating a robust body able to tolerate tough surroundings and extended durations.

Supplying peerless strength and durability, stabilized soil equipment are indispensable for multiple projects, including roadways, spans, trails, and residential/commercial works. By leveraging the natural strength of earth, these machines provide a sustainable method for base building.

Cement Facility Options for Each Venture

We appreciate every erection venture is particular and necessitates personalized concrete methods. Thus, we grant assorted modifiable building material plant opportunities satisfying your specialized prerequisites. Whether you're working on a large-scale infrastructure project or a smaller, localized endeavor, we have the expertise and equipment to deliver high-quality concrete consistently. Our coalition of advisors works alongside clients to construct concrete manufacturing systems enhancing efficiency, reducing surplus, and delivering outstanding products. Our offerings include batching plants, blending units, aggregate operation devices, pumping instruments, and monitoring frameworks. Our enthusiasm for customer pleasure is consistent. We offer unwavering help from primary guidance to installation and ongoing repairs. Permit us to support your growth, stepwise in construction.Mobile Cement Mixing Stations: Adaptable and Robust

Inside the fabrication environment, performance and resilience are significant. Transportable cement mixing systems deliver an exclusive remedy to these requirements, granting constructors superior versatility and mobility on-site. Unlike traditional stationary plants, these units can be easily transported to various locations, eliminating the need for costly and time-consuming setup and teardown processes. That supports smooth activities, minimized schedules, and major financial savings.

The relocatability of mobile cement mixing stations introduces diverse potentials for builders. They provide effective support for projects in isolated areas, limited metropolitan locations, or wherever traditional plants fall short. Additionally, the ability to quickly relocate plants between jobs allows contractors to maximize their resources and minimize downtime.

- Enhanced Output: Minimize travel time and get projects moving faster with on-site mixing.

- Reduced Costs: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Heightened Adjustability: Tackle a wider range of projects in diverse locations.

With their compact design and robust performance, mobile concrete mixing plants are revolutionizing the construction industry. They provide contractors with the tools they need to deliver projects efficiently, cost-effectively, and with unwavering precision.

Meticulous Concrete Generation Using Leading Technologies

Latest concrete assembly undergoes a substantial development because of progressive machinery. Digital automation is adopted to realize remarkable precision along all stages, involving constituent batching to end delivery. As a result, concrete shows superior strength, lowering residue and enhancing input usage. Recording apparatuses contribute critical functions in amassing prompt data about multiple parameters during production. Acquired metrics are reviewed to find avenues for refinement, helping manufacturers to regularly elevate processes and provide dependably fine concrete. The benefits of precision concrete production extend beyond the manufacturing process itself. Boosted aspects of progressive concrete generate solid constructions, reducing restoration costs and prolonging asset lifespans.Promoting a Green Era with Sophisticated Fabrication Equipment

The infrastructure field faces a rapid change, propelled by the critical necessity to decrease its environmental effect. Progressive fabrication apparatuses have essential roles in this evolution towards green practices. Electrically powered tools achieve commonality, reducing emissions and acoustic interference. Moreover, improvements in engineering result in highly effective machinery that utilizes materials intelligently. These innovations improve environmental health and elevate performance for infrastructure enterprises.

The acceptance of ecological plans in the assembly realm is critical for achieving a durable world. By deploying innovative equipment and technologies, the field aids in maintaining planet health for future times.

A Steadfast Companion in Structural Development: Strong Devices, Experienced Support

In developing upcoming structures, trustworthy collaborators are vital. We supply that backing. Our selection includes powerful durable tools crafted to overcome demanding tasks. Our instruments integrate advanced systems offering excellent efficiency and output.

Yet, we act as more than simple tool vendors. Our coalition of trained analysts provides extraordinary guidance along the procedure. From design to overhaul, we support you in enhancing your construction initiatives.

- We deliver full training schemes to train your employees for proper and safe instrument operation

- We also offer remote expert assistance to resolve your inquiries and issues promptly

- Our resolve concentrates on offering apparatus and proficiency vital to meet your erection ambitions

Heavyweight Cement Mixing

Huge creation efforts call for concrete methods meant to endure strong pressure and tension. Robust cement mixing systems meet this demand by providing durable blends customized for overpasses, tall buildings, and passageways. Such particular systems use tough devices equipped to deal with extensive supplies of elements, binders, and modifiers. Careful evaluations maintain reliable quality and observance of tough structural codes

- Cutting-edge management solutions raise mixing consistency and efficiency

- Adopting advanced binders fortifies the durability of the substance

- Resilient batching systems provide critical support for erection advancement impacting habitual activities

Boosting Construction Processes: Enhanced Mixing and Logistics

Amid the quick sphere of creation, capacity is crucial. A significant feature for accomplishment depends on improving your fusion and supply systems. With the application of proven techniques, you can markedly lessen discard, curtail spending, and elevate aggregate throughput. A vital component consists of selecting compatible mixing technology for your exclusive criteria. Whether employing a flexible blender for modest jobs or a heavy machinery for vast operations, confirm it handles the volume of ingredients required. Likewise, upgrade your distribution channels to lessen transit durations and gasoline costs.

- Utilizing a process to record input usage aids in detecting possibilities for optimizations

- Systematic inspection of your amalgamation and delivery systems is important to copyright maximum operation and longevity

Complete Concrete Construction Process

Amid the realm of erection, concrete plays a role as a pillar of durability and robustness. Affording holistic support across all phases of your cement task is our motivation. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted Fixed concrete mixing plant to your particular demands|From preliminary drafting to ultimate execution,