Within the tough environment of power frameworks, busbar fabrication involves distinctive difficulties. Spanning detailed fabrication to optimal deployment, every section insists on focused precision and inventive plans. Cutting-edge manufacturing practices have upgraded busbar fabrication, generating high-level effectiveness and competence. Refined apparatus including autonomous carving, flexing, and fusion technologies promise precision, steadiness, and lowered waiting times.

Such upgrades transform into discernible values for consumers. Busbar products are manufactured swiftly and steadily, limiting delays and enabling punctual finalization. Besides that, the fundamental fineness of advanced practices leads to busbars exhibiting better conduction and longevity, securing trustworthy power distribution over duration.

- Robotic cropping: Accurate sectioning techniques secure correct and consistent measurements, lowering discard and amplifying general output

- Twisting ability: Innovative molding equipment fashions precise folds and bends, allowing elaborate busbar schemes and individual configurations

- Uniting prowess: Mechanical fusion operations provide sturdy and trustworthy connections, affirming busbar fabrication cohesion

By deploying these revolutionary tactics, industries can augment busbar assembly processes, achieving unsurpassed effectiveness and results. The progression of power networks hinges on creativity, featuring current busbar assembly technologies as prime movers.

Correct Power strip Shaping in support of Power Quality

Achieving optimal electrical performance requires precise and meticulous busbar bending techniques. Electrical strips, the fundamental mediums distributing voltage, must be bent with superior accuracy to provide efficient energy passage and decrease resistivity. This meticulousness is vital in impeding heat concentration and likely impairments to electrical components. By employing cutting-edge shaping equipment and expert workmanship, producers fabricate conductors satisfying tough criteria across various power uses.

- Outstanding current flow

- Lessened current decay

- Enhanced network dependability

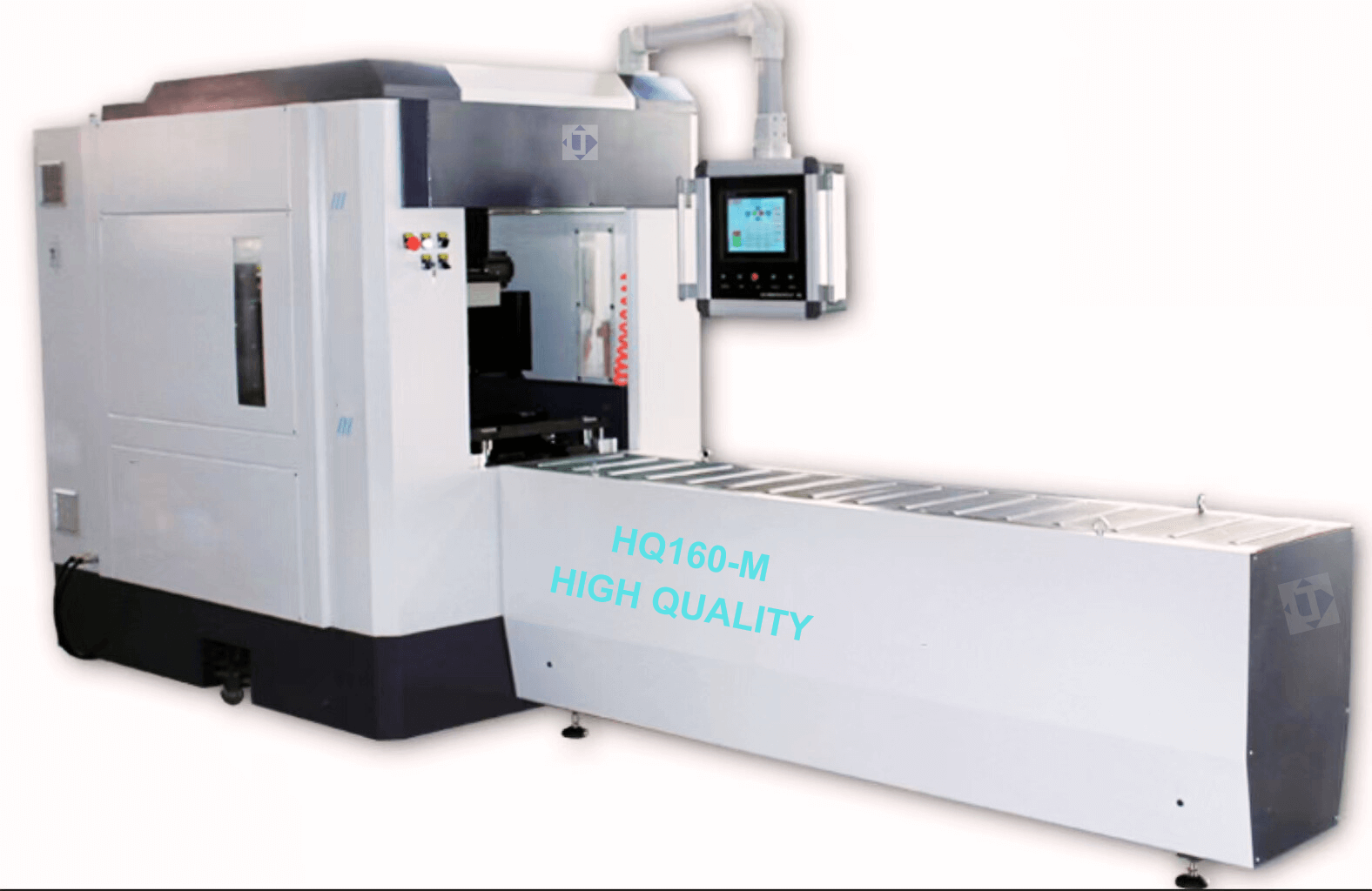

Modernize Personal Busbar Assembly using a tri-functional conductor unit

Do you want a robust technique to control your electric contact production necessities? Explore the pioneering triple-operation current device! This all-in-one mechanism unifies three fundamental processes into one device, presenting a thorough strategy for carving, curving, and hole punching electric bars with exceptional precision.

- Benefit 1

- Merit 2

- Asset 3

Created for endurance and straightforward use, the hybrid fabrication system strives to furnish remarkable products while trimming operational breaks. Invest your busbar production process today with this indispensable tool!

Automated Busbar Creation: Maximizing Throughput and Carefulness

The processing market perpetually endeavors to increase effectiveness and consistency. Conductor fabrication, an essential activity in power engineering, follows suit. Mechanized current bar assembly methods are altering practices by notably raising productivity while securing premium exactness. These refined frameworks use premier technology including computer aid and beam clipping to build copper strips with outstanding evenness and promptness.

Via fabricating mechanical routines, these strategies afford operators the chance to focus on elevated tasks. This progress raises comprehensive capacity and curtails inaccuracies, delivering top-tier copper strip devices. Moreover, intelligent electric contact manufacturing technologies contribute improved control and data scrutiny tools, giving valuable views of assembly operations and fostering ongoing upgrades.

Sophisticated Electrical contact Crafting Methods

The push for robust circuitry designs escalates motivating developments in electrical bar handling. Sophisticated strategies are surfacing restoring this discipline, enabling construction of notably accurate and efficient copper strips. These developments encompass sophisticated slicing methods like ray ablation and electrical spark cutting (EDM), delivering superior precision, surface polishing, and elemental removal. Also, the merger of CAD and CAM technologies empowers precise monitoring of outline and prevents disposal

- Streamlined procedures in busbar machining streamline production, increasing efficiency and reducing lead times|Automated apparatuses in conductor manufacturing optimize workflows, boosting productivity and cutting delays|Mechanized tools in power strip fabrication enhance output, augmenting speed and minimizing downtime|Computerized devices in current bar assembly improve cycles, elevating effectiveness and shortening turnarounds|Digitized systems in copper bar processing advance throughput, maximizing rapidity and trimming wait periods|Robotic equipment in electric contact crafting upgrade sequences, heightening competence and limiting stoppage|Intelligent machines in charge carrier production refine operation, increasing capacity and lowering processing times|Streamlined units in electrical bar treatment boost productivity, accelerating results and decreasing idle intervals

- Tracking technologies play a crucial role in ensuring the quality and consistency of machined busbars, detecting any deviations from specifications|Observation gadgets hold vital importance in maintaining integrity and uniformity of fabricated conductors, identifying anomalies relative to standards|Measurement technologies serve critical functions in preserving excellence and regularity of manufactured power strips, pinpointing divergences against criteria|Detection instruments perform key roles in upholding precision and stability of constructed current bars, recognizing variants from requirements|Tracking mechanisms are essential in securing accuracy and uniformity of processed copper strips, signaling disparities from benchmarks|Evaluation tools have importance in guarding fidelity and steadiness of crafted electric contacts, flagging inconsistencies to parameters|Monitoring devices are instrumental in affirming reliability and evenness of assembled charge carriers, spotting departures from norms|Data analytics systems are fundamental in assuring quality and homogeneity of machined electrical bars, marking deviations against specifications

Optimizing Conductor Processing with Advanced Equipment Optimizing

Inside progressive circuitry foundations, improving copper bar fabrication is crucial. Current improvements in assembly apparatus have innovated processing, enabling makers to realize excellent current bars with boosted performance and meticulousness. High-speed automated cutting systems ensure accurate and consistent dimensions, in addition exquisite binding equipment furnish robust and sure fastenings. The modernization accomplishes contracting production cycles along with limiting material refusal, encouraging sustainable systems.

Benefits of Automation in Busbar Manufacturing

Electrical bar processing enjoys considerable transition resulting from adopting advanced robotics. Automated systems are revolutionizing various aspects of the process, from cutting and bending to welding and testing. This progression renders several upsides including enhanced manufacturing, improved product accuracy, curtailed workforce expenses, and lowered faults.

- Thereby, electrical bar producers perform outstanding outputs faster, fulfilling challenging standards of different fields

- {Furthermore, automation enhances workplace safety by reducing manual labor involving workers to potentially hazardous conditions|Moreover, robotics improves occupational health lowering physical tasks exposing staff to risky environments|Additionally, intelligent systems boost labor protection by minimizing manual efforts subjecting employees to unsafe situations|Besides that, computerized operations augment workforce security by cutting down physical jobs placing workers in dangerous settings|Further, mechanized functions uplift occupational safety by decreasing manual duties involving personnel in harmful conditions|Also, digitized procedures raise workplace protection by lessening human effort exposing laborers to hazardous areas|Likewise, automated workflows increase employee security by limiting manual tasks facing crew to risky circumstances|Similarly, streamlined processes improve staff safety by reducing physical labor subjecting workers to perilous zones

Henceforth, electrical bar fabrication combined with digitization is likely to evolve significantly

Advanced Power strip Manufacturing Equipments

Throughout electric circuitry engineering, robust current bar manufacturing mechanisms are vital for developing consistent and potent power systems. Refined tools incorporate high-tech techniques to manage copper strips with exceptional correctness and swiftness. Covering piercing and shearing along with folding and crafting, these adaptable systems perform multiple jobs accurately, assuring maximum efficacy and endurance of finished items. Utilizing durable components and sophisticated automation technologies allows these machines to function effectively and dependably throughout challenging environments

- Programmable control systems ensure precise alignment of busbars throughout the processing cycle|Smart regulation frameworks guarantee accurate positioning of conductors during entire fabrication operations|Programmable management solutions provide exact arrangement of power strips throughout production sequences|Computer-aided supervision platforms deliver precise orientation of current bars across processing steps|Mechanized monitoring tools secure accurate setup of copper strips during manufacturing phases|Digitized adjustment apparatuses facilitate exact alignment of electric contacts through assembly stages|Robotic command mechanisms maintain precise positioning of charge carriers during fabrication runs|Streamlined control devices assure accurate layout of electrical bars throughout machining procedures

- Tough construction withstands the rigors of continuous operation in industrial settings|Solid manufacturing sustains harsh demands of nonstop use in factory environments|Hardy fabrication endures stresses of prolonged function within production areas|Reinforced design tolerates strains of sustained activity under workshop conditions|Stout assembly resists impact of relentless service inside industrial facilities|Tenacious build copes with pressures of endless operation in manufacturing plants|Resistant structure faces challenges of unceasing work across factory contexts|Hardwearing framework stands up to trials of nonstop performance in production sites

- Expedited processing reduces production time and increases overall productivity|Effective machining shortens manufacturing periods and boosts total output|Quick fabrication lowers operation duration and heightens aggregate yield|Speedy manufacture cuts assembly intervals and enhances combined efficiency|Accelerated production diminishes process time and advances broad throughput|Expedited creation truncates working spans and improves overall performance|Prompt processing contracts operational lengths and raises total capacity|Fast development shrinks fabrication cycles and escalates general productivity

Adopting sophisticated electric contact assembly instruments has modernized manufacture processes, enabling creation of advanced, reliable transmission infrastructures fulfilling mounting requests of contemporary electric implementations.

Cutting-Edge Conductor Flexing aimed at Complicated Structures

Among the altering ground of energy flow engineering, exactitude in object assembling is crucial. Current bars, fundamental pipelines channeling energy, occasionally involve detailed contouring plans to address diverse deployments. Standard flexing approaches commonly underperform with elaborate configurations, producing poor outcomes. Embracing modern copper bar folding machinery reforming processes by shaping elegant contours with excellent adjustability.

- Deploying ultra-modern CNC systems, these progressive devices guarantee faultless identical bends

- The code running these apparatuses includes straightforward controls, facilitating engineers to build sophisticated folding layouts comfortably

- Besides that, the systems efficiently cooperate with varied materials, enlarging its coverage across multiple factory sectors

The breakthrough in electric contact bending helps technicians to realize elaborate plans, achieving enhanced power flow and minimized manufacturing charges.

Harnessing Success employing 3D Busbar Fabrication

{Revolutionizing power distribution systems, 3D busbar fabrication offers an innovative approach to optimize efficiency and performance|Transforming energy transmission networks, three-dimensional conductor crafting provides a novel method 3 in 1 busbar machine to enhance productivity and output|Changing electric supply architectures, 3D power strip making introduces a fresh path to boost effectiveness and results|Updating circuitry distribution frameworks, three-dimensional current