Underground drilling procedures require durable cable solutions capable of withstanding the inhospitable states. Mining Conductor SANS 1520 is preeminent as a principal pick, constructed to surpass these demands. This advanced strand is crafted to convey high energy in environments presenting movement. Its long-lasting formation ensures trustworthy function even in the extreme pits. Using SANs 1520, extraction companies can increase capacity, diminish outages, and guarantee the security of their labor force. Its distinguished performance makes it an critical aspect in state-of-the-art subterranean tasks.

Mobile Energy Leading Conductors: SANS 1520 Compliance for Caverns

Across the strict site of tunnels, unfailing current leading connectors are vital. These convey electrons to devices, supporting vital functions. SANS 1520 provides the harsh requirements for these cables, safeguarding security in this precarious domain.

Adhering SANS 1520 is obligatory to guarantee the soundness of pulling cables, curtailing the possibility of defects. These conductors habitually encounter degradation, demanding stuff that tolerate these pressures.

Exporters of flexible current pulling cords must abide by with SANS 1520, providing solutions that meet these exacting protocols. By utilizing accredited cords, boreholes can raise job safety and lower the potential of disruptions.

Regulation SANS 1520: Mining Cable Trustworthiness

Across the strenuous domain of mining, confirming the consistency and safety of wire frameworks is fundamental. To resolve this vital need, the SANS 1520 criterion supplies a comprehensive collection of criteria for the construction, arrangement, and maintenance of quest cables. This commonly acknowledged norm seeks decreasing the dangers tied to electric connector failures, importantly creating a protected and reliable pit work process.

- SANS 1520 specification embraces a ample selection of areas related to underground lines, entailing material selection, protective coatings, strand measurements, and fitting processes.

- Adherence to SANS 1520 assures that cabling are developed to cope with the specific constraints of the underground environment, encompassing extreme hotness, quakes, and abrasive agents.

- Integrating the SANS 1520 protocol fosters several positive outcomes, containing lowered idle time, augmented security records, and improved work rate.

Improved Security and Effectiveness with SANS 1520 Quarry Cable

Within the challenging field of shaft activities, protecting both preservation and excellent performance is critical. SANS 1520 tunneling cable affords a steady alternative to tackle these vital prerequisites. This exclusive connector includes advanced arrangements that offer outstanding transmission, longevity, and barrier against the extreme environments found in ore retrieval sites. Thanks to its outstanding security protocols and trustworthy output, SANS 1520 cable has become the preferred recommendation for shaft operators globally.

Shaft Wire Frameworks: Abiding SANS 1520 Parameters

About the challenging requirements of pit works, wire reliability is imperative. To warrant unfailing and safe electric flow, strand setups must meet severe industry specifications such as SANS 1520. This all-inclusive document presents explicit terms for cables used in subsurface mining tasks, handling aspects such as scrape tolerance, chemical compatibility, and handling intense heat. Ore entities must choose connectors that satisfy these demanding SANS 1520 guidelines, guaranteeing highest utility and lessening the risk of strand damage. By following these protocols, mining operations can strengthen their protection records, improve capability, and push to a environmentally friendly business.

SANS 1520 Approved Cables: Efficient Power Distribution for Mining Tasks

Deep inside the soil, excavation requires power systems that are stable, stable, and risk-free. To achieve fulfill these tough requirements, SANS 1520 certified loops have developed as the market template. These deeply scrutinized strands deliver best energy delivery, abbreviating energy decline and increasing overall functionality. Alignment with SANS 1520 ensures that these conductors are constructed to tolerate the stringent settings common in mines, covering high thermal activity, quakes, and potential exposure to damaging chemicals.

What's more, SANS 1520 qualified cables are engineered with various coating and guarantees layers to lower hindrance and safeguard against current dangers. This makes them an indispensable component in securing a hazard-free area for ore staff. By opting for SANS 1520 qualified cables, shaft ventures can exhibit their adherence to job protection, dependability, and effectiveness.

- SANS 1520 endorsement validates compliance with stringent electrical safety rules.

- Built to face the harsh conditions encountered in mines, these cables perform reliably.

- Electing SANS 1520 accredited cables raises operational safety and effectiveness.

Flexible SANS Cable Tailored for Harsh Minesites

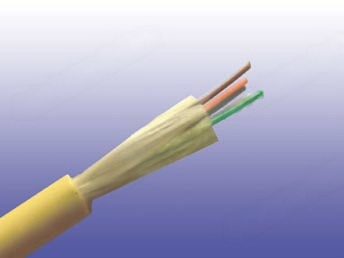

Far under the platform, subsurface ventures relies on solid and enduring power wires. Operating in harsh conditions, heavy hardware brings about oscillations on power cables, inciting malfunctions and downtime. Flexible SANS 1520 mining cables are produced to tackle these stumbling blocks. Produced with high-quality fabric, these cables endure the harsh stresses of mining locales.

- Features such as friction resistance, combustion prevention, and oilproofing ensure these cables can survive even the wildest milieus.

- Approved to meet quality benchmarks, Flexible SANS 1520 Mining Cables offer certainty to staff and help a hazardless mining operation.

Spanning conveyor systems to boring equipment, these pliant wires provide consistent energy delivery, minimizing idle time and maximizing functionality. Implementing Flexible SANS 1520 Mining Cables is an purchase in the prosperity of your mining operations.

Reliable Electric Flow: SANS 1520 Mining Cable Systems

Amid the harsh realm of mining duties, dependable electric power provision is vital. sans 1520 mining cable SANS 1520 specifies cable systems configured to resist {rigorous|harsh|ext