Launching our comprehensive scrutiny on thermoplastic 6, often named like synthetic fiber 6, ranks high to be a commonly deployed production material providing a impressive combination of properties. Its essential durability, coupled with noteworthy compound resistance, causes it a ideal possibility across a diversity of uses, including from automotive parts and electricity connectors to weaving fibers and long-lasting packaging. It versatility is further boosted by its good abrasion resistance and mildly low water absorption rates. Understanding the characteristic characteristics of PA 6 – comprising its softening point, traction strength, and force resistance – is paramount for efficient material preference in design and production processes. Consider also its behavior under shifting environmental conditions, as these factors can dramatically affect its performance.

Polyamide Functionality and Utilizations

Polyamide, commonly known as synthetic fiber, exhibits a remarkable union of properties that make it suitable for a expansive range of employments. Its exceptional tenacity, alongside its immunity to agents and attrition, grants it excellent endurance in exacting environments. Fiber industries heavily depend on polyamide for fabrication hardwearing cables and cloths. Beyond garments, it's habitually exercised in transportation components, power connectors, production apparatus, and even client materials. The faculty to shape it into detailed contours further augments its utility across various branches. Recent innovations center on boosting its caloric equilibrium and minimizing its liquid engagement for even augmented particular operations.

Crystal Augmented Nylon 6: Strengthened Mechanical Properties

The incorporation of microcrystalline bismuth compounds, or "bismuth nanoinclusions", into Nylon 6 matrices has emerged as a valuable strategy for achieving markedly improved mechanical performance. This hybrid material exhibits marked gains in tensile strength and stiffness compared to the preset Nylon 6 resin. Specifically, the dispersion of these "nanofillers" acts to inhibit polymer chain rearrangement, leading to a greater resistance to straining under load. Furthermore, the presence of MCBs often contributes to a attenuated tendency for plastic flow over time, improving the durable dimensional stability of components. While challenges remain in ensuring uniform "deployment" and avoiding agglomeration, the benefits in terms of overall strength are apparent and drive ongoing research into optimized processing techniques.

PA6 Nylon: Material Resistance and Longevity

PA6 nylon, a versatile polymer, exhibits exceptional elemental resistance across a broad spectrum of substances. It demonstrates impressive performance when exposed to hydroxides, acidics, and various fuel liquids, making it suitable for demanding applications within the industrial sector. Beyond its non-reactivity to chemical attack, PA6 nylon’s inherent robustness contributes to its extended service term. This robust nature, coupled with its ability to bear impact and abrasion, ensures dependable performance even under stressful conditions. Furthermore, the material's excellent mechanical properties facilitate its use in components requiring both elemental protection and lasting strength.

Explaining Nylon 6 vs. PA6: The Identification Confusion

A common point of mix-up arises when discussing nylon materials: the terms "PA6" and "Polyamide 6". The authenticity is they stand for the very identical polymer. "PA" stands for "Polyamide," which is the typical class for this family of plastics. Therefore, Nylon 6 is simply a distinct name for a Polyamide 6. The "6" denotes the number of carbon atoms betwixt the nitrogen atoms in the polymer chain – a defining property that determines its properties. So, whether you hear "N6" or "Fiber 6," rest certain that you're communicating the uniform material, known for its strength, bendability, and resistance to erosion.

Fabrication and Implementation of Nylon 6 Polyamide

The polyamide of Nylon 6's fabrication presents unique complications demanding precise regulation over several key processes. Primarily, polymerization typically occurs via a ring-opening reaction of caprolactam, facilitated by catalysts and careful temperature regulation to achieve the desired molecular load and polymer properties. Subsequent melt forming is a fundamental step, converting the molten polymer into fibers, films, or molded components. This is frequently followed by solidifying to rapidly solidify the material, impacting its final configuration. Injection casting is also widespread, involving injecting the molten nylon into a cavity under high pressure. Alternative strategies include extrusion pneumatic molding for producing hollow articles, and pultrusion, beneficial for creating composite profiles with high tensile toughness. Post-processing stages might involve heat curing for further enhancing mechanical productivity, or surface adjustment for improved adhesion or aesthetic qualities. Each strategy requires stringent monitoring to maintain consistent product grade and minimize defects.

MCB Adjustment of Nylon: A Case Study

A recent project at our site focused on the meaningful impact of Microcrystalline Bacterial (MCB) use on the structural parameters of nylon-6,6. Initial insights revealed a remarkable improvement in tensile durability following MCB interaction, particularly when combined with a carefully coordinated temperature profile. The unique MCB strains utilized demonstrated a manifest affinity for nylon, leading to particularized alterations in the polymer arrangement. This, in turn, curtailed the risk of rapid failure under cyclical burden. Further analysis using sophisticated microscopy approaches unveiled a developed crystalline configuration, suggesting a suspected mechanism for the exhibited enhancements. We are presently researching the scalability of this procedure for mass production exploitation.

Constituent Selection Points: Nylon 6, PA6, and MCB

Choosing between resin 6, PA6, and MCB (Milled Cellulose Board) presents a unique engineering challenge, demanding careful assessment of application requirements. While polyamide 6 excels in impact durability and offers good material compatibility—especially with oils—it can be susceptible to moisture absorption, which affects its dimensional stability and mechanical qualities. PA6, essentially a synonym for synthetic fiber 6, follows the same trends, although specific grades might exhibit minor divergences in performance. Conversely, MCB, a biodegradable material, brings a completely unique set of properties to the table: it's biodegradable, can be easily worked, and offers a pleasant aesthetic, but its mechanical operation is significantly diminished compared to the synthetic fiber options. Consequently, deliberation of temperature, load, and environmental factors is important for making an informed preference.

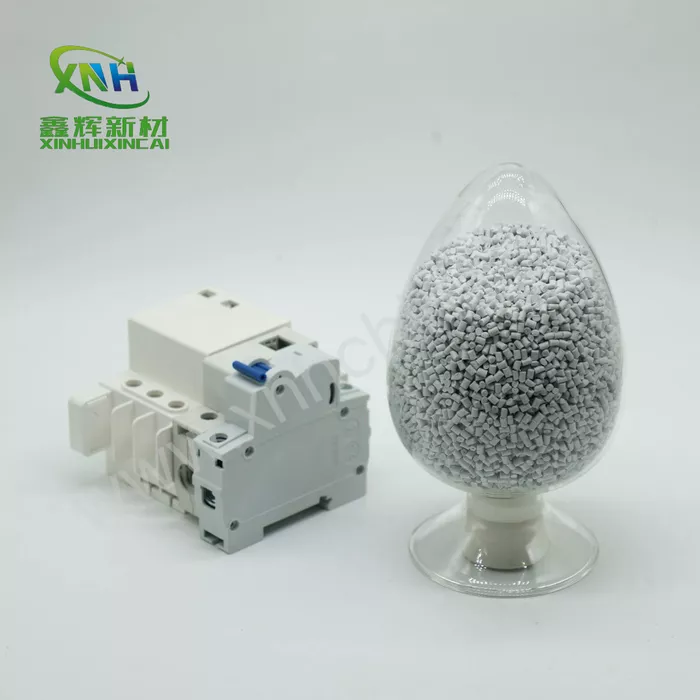

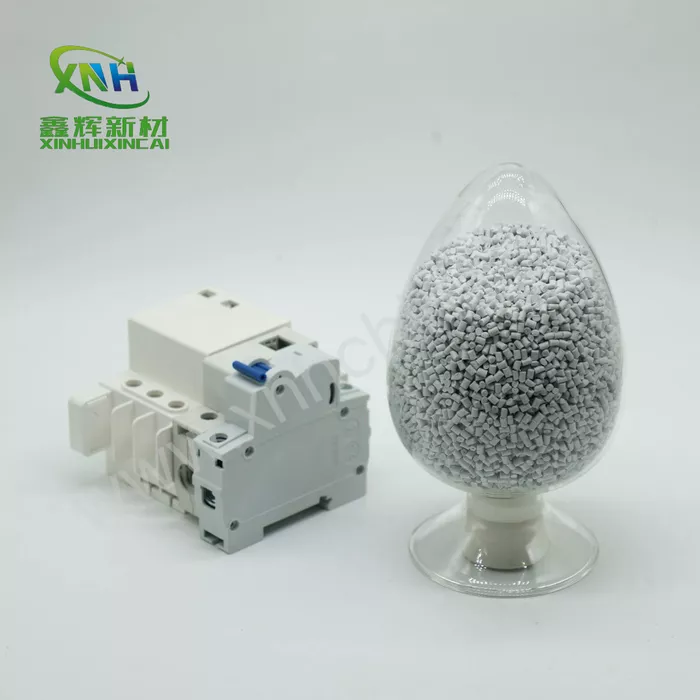

Deployments of Polyamide 6 (PA6) in Construction

PA6, or PA6, demonstrates considerable versatility, finding widespread application across various fabrication disciplines. Its constitutional combination of considerable tensile strength, remarkable abrasion resistance, and sufficient chemical resistance makes it notably suitable for demanding functions. For case, within the vehicle sector, PA6 is typically employed for segments like combustible lines, cooling hoses, and numerous under-the-hood units. The weaving industry persists to utilize PA6 for producing durable and yielding threads, while in consumer goods, it's habitually found in possessions such as mechanism housings and electric tool bodies. Furthermore, advancements in ingredient science are unceasingly broadening PA6’s capacity into areas like medical implants and niche construction apparatus. Recent research efforts are also targeted on boosting PA6's heat stability and stress resistance, supplementary expanding its extent in specialized frameworks.

Thermal and Mechanical Behavior of MCB-Nylon Formulations

A comprehensive analysis was undertaken to scrutinize the warming and mechanical performance of MCB (Mineral Clay Binder)-reinforced nylon composites. The analysis involved employing both Differential Scanning Calorimetry (DSC) for thermal transition detection and a range of mechanical assessments, including tensile hardness, flexural rigidity, and impact durability. Initial results suggest a significant boost in the stiffness and robustness of the nylon matrix upon MCB incorporation, however, a corresponding drop in ductility was observed. Further, the inspection uncovered a complex relationship between filler portion and the resulting engineering aspects, suggesting an best loading level for achieving a desired balance of effectiveness features. Subsequent work will direct on perfecting the dispersion of MCB within the nylon matrix to maximize integrated effects.

Polymer Types 6 Breakdown and Lengthy Phase Durability

The built-in activity of Nylon 6 polyamide compositions is significantly modified by their inclination to breakdown over sustained periods. This case isn't solely associated to warmth exposure; forces such as humidity, radiant radiation, and the exposure of inflammatory agents also exert a crucial role. Hence, maintaining ongoing term durability requires a comprehensive insight of these weakening mechanisms and the usage of proper maintenance schemes. To sum up, preventative steps are necessary for securing the stable capability of Nylon 6 components in harsh situations.

MCB

MCB